On December 20, 2025, a landmark event occurred at Shougang Shuicheng Steel Group in Liupanshui, Guizhou Province: the world’s first commercial supercritical CO₂ (sCO₂) power generation unit—“Super Carbon One”—officially entered commercial operation. This global demonstration project, led by the Nuclear Power Institute of China (under CNNC), in collaboration with Jigang International Engineering Technology Co., Ltd. and Shougang Shuicheng Steel Group, marks the transition of sCO₂ waste heat recovery technology from laboratory to industrial application, establishing China’s global leadership in this cutting-edge field.

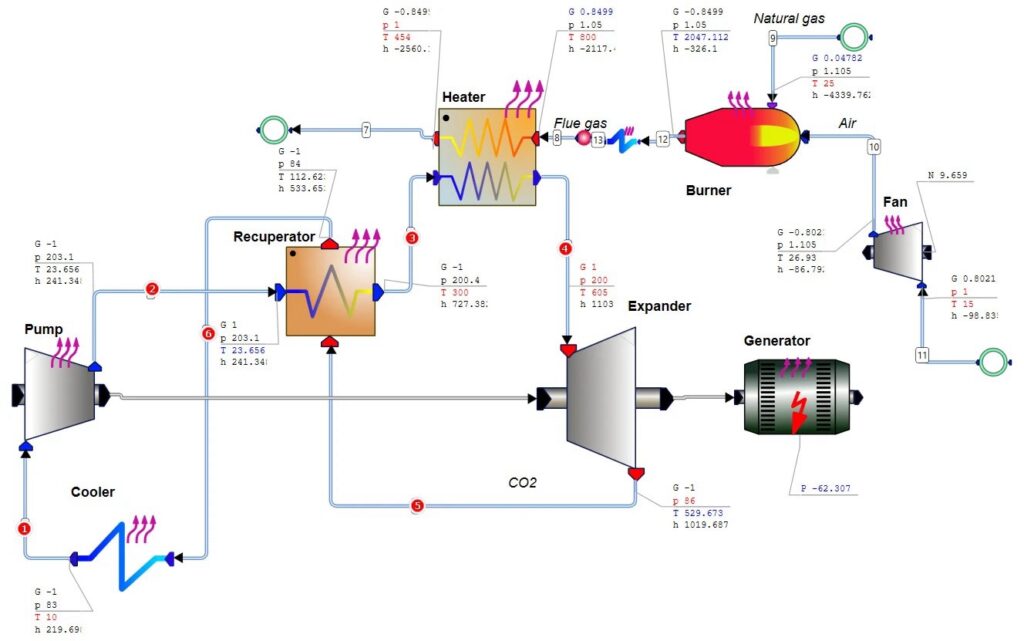

The images above illustrate typical sCO₂ Brayton cycle schematics and layouts, showcasing the compact system design compared to traditional setups (footprint reduced by about 50%).

Limitations of Traditional Power Generation: Why a New Working Fluid is Needed

For over 200 years, human electricity production has relied primarily on the steam Rankine cycle: heating water to produce steam that drives a turbine. This “boiling water” approach achieves efficiencies above 40% at high temperatures and pressures, but in mid-to-low temperature waste heat recovery (e.g., 300-600°C exhaust from steel or cement industries), efficiency often falls below 30%, with bulky equipment, high water consumption, and slow start-stop times.

“Super Carbon One” uses supercritical CO₂ as the working fluid, revolutionizing this paradigm. CO₂ reaches its critical point at just 31.1°C and 7.38 MPa—far lower than water’s 374°C and 22.1 MPa—making it easy to enter the supercritical state. In this phase, CO₂ combines gas-like low viscosity with liquid-like high density, becoming an ideal “super fluid” for efficient heat-to-power conversion.

The demonstration project is a 2×15 MW (total 30 MW) unit targeting waste heat from steel sintering ring coolers:

- Power generation efficiency improved by over 85%;

- Net output increased by more than 50%;

- Footprint reduced by 50%;

- Start-stop in mere minutes;

- Annual revenue increase of nearly 50 million RMB, payback period around 3 years.

Core Principle: Recompression Regenerative Brayton Cycle

“Super Carbon One” employs a closed recompression regenerative Brayton cycle, avoiding phase changes and keeping the fluid supercritical throughout. ”

The images above show typical sCO₂ cycle flow diagrams, highlighting the “two machines, three heat exchangers” core components.

Cycle process:

- Low-temperature sCO₂ from the turbine outlet is cooled near the critical point, then split for compression (main compressor + recompressor, minimizing work near critical point).

- Compressed sCO₂ is preheated in low- and high-temperature recuperators.

- It enters the heater to absorb waste heat (up to ~500-600°C).

- High-temperature, high-pressure sCO₂ expands in the turbine to drive the generator.

- Exhaust heat is recovered in recuperators, closing the loop.

The images above are temperature-entropy (T-S) diagrams of the sCO₂ recompression cycle, where recuperation brings the process closer to the ideal Carnot cycle, achieving 45-55% efficiency.

Key innovations:

- Turbine and compressors: High-speed (tens of thousands RPM), compact (volume 1/10 to 1/20 of steam turbines). 9 “LARGE” 10 “LARGE”

- Heat exchangers: Printed circuit heat exchangers (PCHE) with micro-channels for extreme pressure/temperature resistance and high efficiency. 12 “LARGE” 13 “LARGE” 14 “LARGE”

Comparison with Traditional Steam Cycle

Aspect Traditional Steam Rankine Cycle sCO₂ Brayton Cycle (“Super Carbon One”) Working Fluid Water/Steam (with phase change) Supercritical CO₂ (no phase change) Mid-Temp Waste Heat Efficiency ~30% >45% (85%+ improvement) Equipment Volume Large Small (1/10-1/20) Start-Stop Time Hours Minutes Water Consumption High Zero (closed loop) Flexibility Poor Excellent (ideal for renewable peaking)

Global Significance and Future Outlook

The U.S., EU, and others have invested heavily in sCO₂ for over a decade, but most efforts remain at 10 MW-scale pilots. “Super Carbon One” is the world’s first megawatt-scale commercial application, validating a fully domestic supply chain.

The technology’s potential is vast:

- Steel/cement waste heat recovery: National potential to save millions of tons of standard coal annually, reducing CO₂ emissions by tens of millions of tons.

- Concentrated solar power/nuclear: 5-10% efficiency gain, 20% cost reduction.

- Geothermal, naval propulsion: Compact and water-free.

“Super Carbon One” is not just a technological breakthrough—it’s a powerful driver for China’s “dual carbon” goals. Starting from the highlands of Guizhou, this quiet energy revolution is reshaping the global landscape of thermal power conversion.